Diabatic capillary tube (a) block diagram (b) P-h diagram Diabatic

4.6 (589) · € 25.00 · En Stock

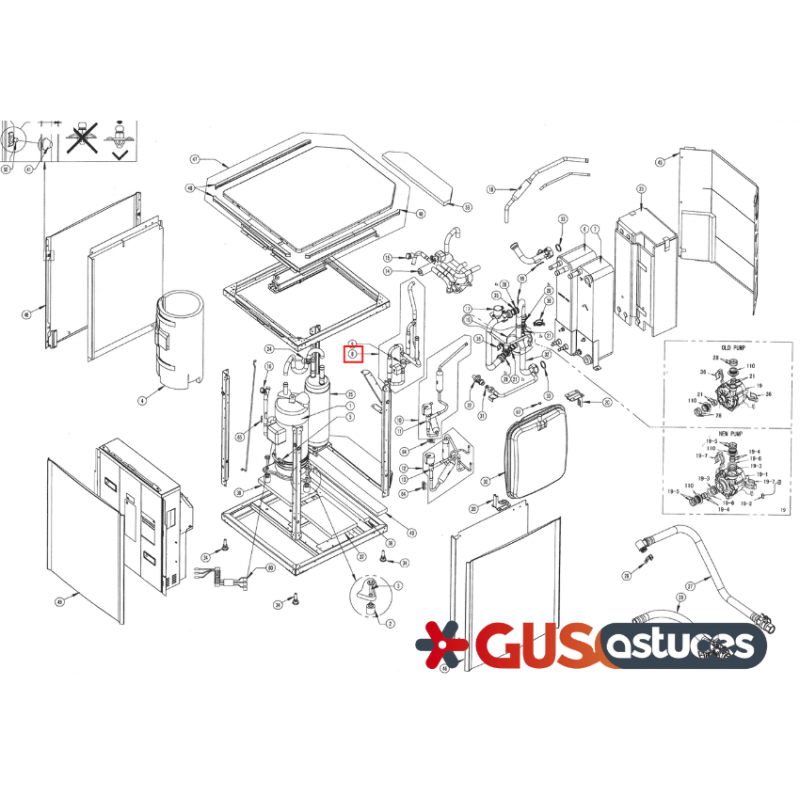

Download scientific diagram | Diabatic capillary tube (a) block diagram (b) P-h diagram Diabatic capillary tube act as heat-exchanger. In a diabatic flow arrangement, the capillary tube is bonded with the cold compressor suction line in a counter flow arrangement as shown in Fig. 2a. In this tube refrigerant expands from condenser pressure to evaporator pressure. As refrigerant expands through capillary tube from high to low pressure (c to d) it transfer its heat to refrigerant passing through the suction line of compressor (a to a') as shown in Fig. 2b. So here liquid region length increases as compare to adiabatic capillary tube. As result of this refrigerating capacity increases, also cause improvement in efficiency of cycle [3-4]. The flow inside the capillary tube of a refrigeration system can be divided into a sub cooled liquid region from the entrance to the point in which the fluid reaches saturated conditions, and a two phase flow region after that point until the end of the capillary tube In Figure 2, the variation of refrigerant temperature and pressure has been plotted against the capillary tube length. The pressure falls linearly in the liquid region of the capillary tube while the temperature remains constant as the flow through capillary tube is considered adiabatic[2-5]. 1.3 Computational Fluid Dynamics During last few decades, significant progress has been made on the development of various types of CFD techniques [7-8] for investigating multiphase or interfacial flows. Among different multiphase models, few prominent models such as volume of fluid, level set, Lattice-Boltzmann, and smoothed particle hydrodynamics have been mostly reported in the literature. At initial stage, these multiphase models were widely used to investigate the isothermal two-phase flows such as motion and deformation of droplets and thin film flows and later on, they were extended to study the phase change problems of boiling and condensation process. In the recent years, several studies have reported the use of volume of fluid method (VOF) model using commercial software for the phase change problems [6]. Liu et al.[4] have successfully implemented the source term in VOF model to analyze the condensation between parallel plates. The phase transformation of flowing fluid usually takes place in a highly unsteady state, where tracking the interface of liquid and vapor phase becomes very from publication: CFD Parametric Investigation for Two Phase Flow of Refrigerant 134a In an Adiabatic Capillary tube | Capillary tubes are widely used as refrigerant flow control device in a small refrigeration systems. Since the flow behavior inside a capillary tube is complex, several physical models are necessary to predict the characteristics of refrigerant flow in the capillary tube. A | Refrigeration, Two Phase Flow and Condensation | ResearchGate, the professional network for scientists.

Auto-regulated Hepatic Insulin Gene Expression in Type 1 Diabetic Rats: Molecular Therapy

Adiabatic capillary tube showing different flow regions and

Dietary Fat and an Exogenous Emulsifier Increase the Gastrointestinal Absorption of a Major Soybean Allergen, Gly m Bd 30K, in Mice1 - The Journal of Nutrition

Diabatic capillary tube (a) block diagram (b) P-h diagram Diabatic

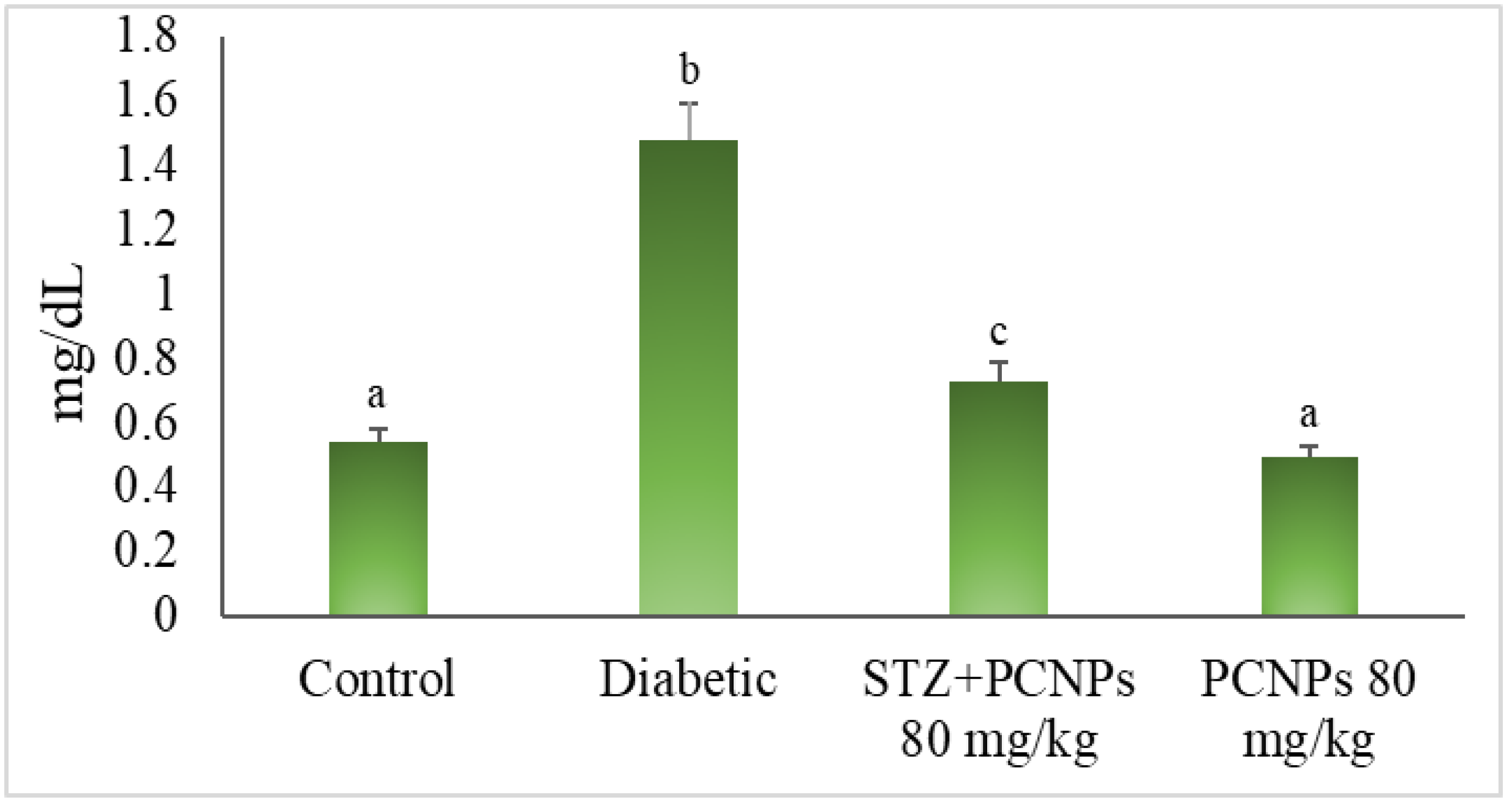

IJMS, Free Full-Text

Metabolites, Free Full-Text

The conducted vasomotor response and the principles of electrical communication in resistance arteries

Flow characteristics of refrigerants flowing through capillary tubes – A review - ScienceDirect

Diabatic capillary tube (a) block diagram (b) P-h diagram Diabatic

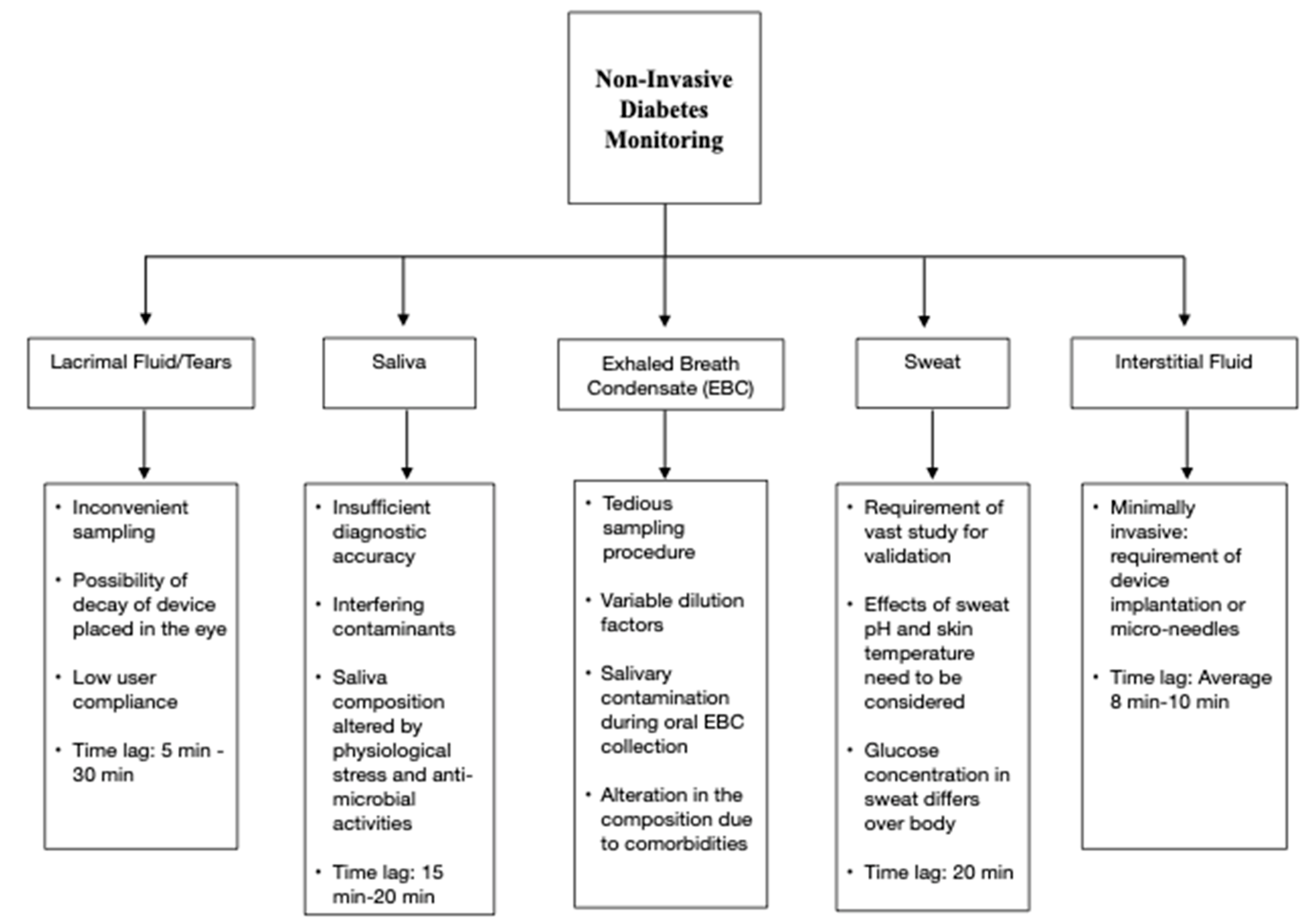

Biosensors, Free Full-Text

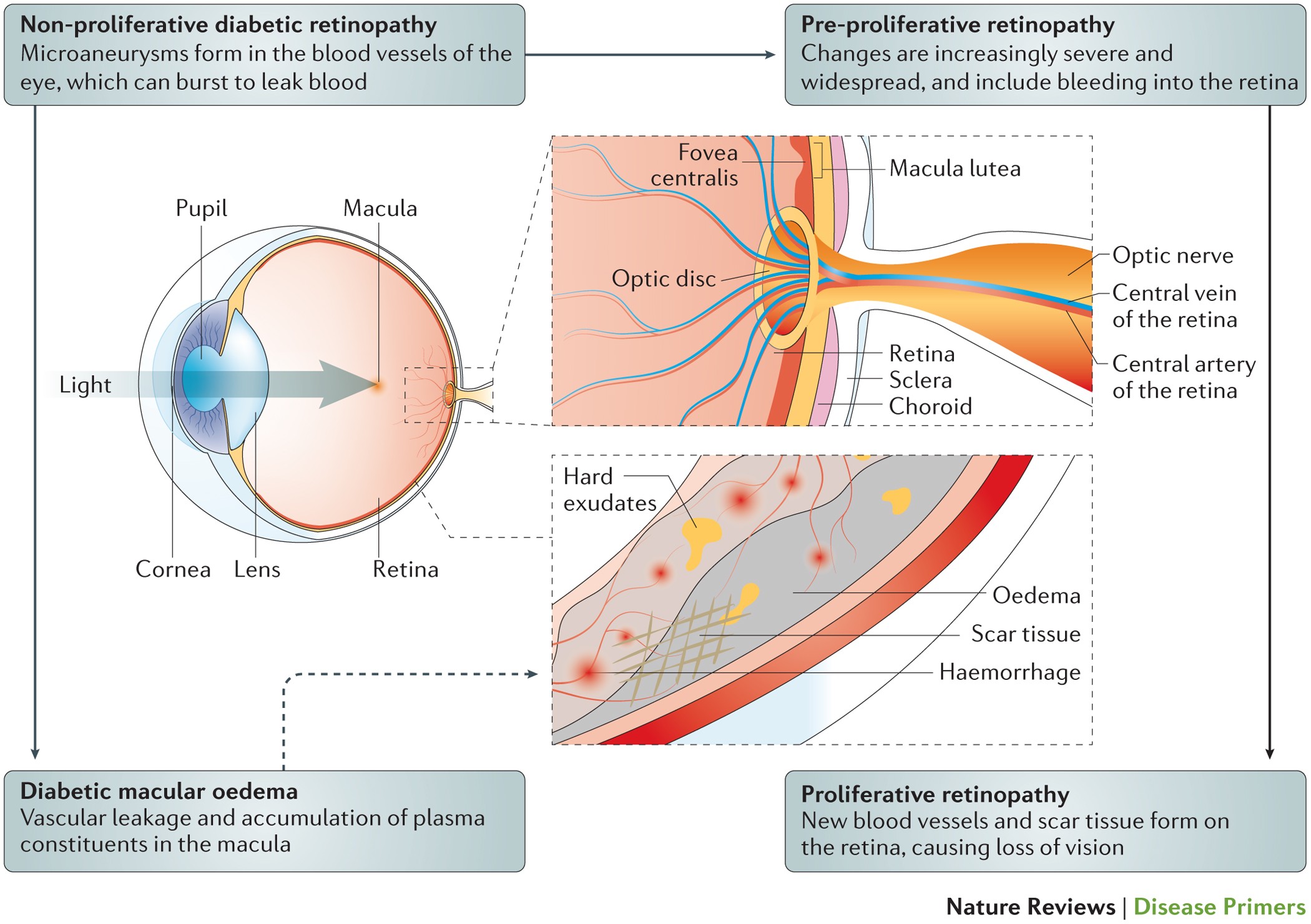

Diabetic retinopathy Nature Reviews Disease Primers