- Accueil

- vacuum film

- Vacuum Bagging Films Take the Heat in Vacuum Infusion - Composites One - Composites One

Vacuum Bagging Films Take the Heat in Vacuum Infusion - Composites One - Composites One

4.5 (523) · € 27.99 · En Stock

Vacuum bagging films from Composites One can withstand high temperatures during vacuum infusion. Discover the benefits of using our advanced films, and see how they can improve the quality and performance of your composite parts.

Avoiding the pitfalls of vacuum infusion processing

Resin infusion and vacuum bagging tubes

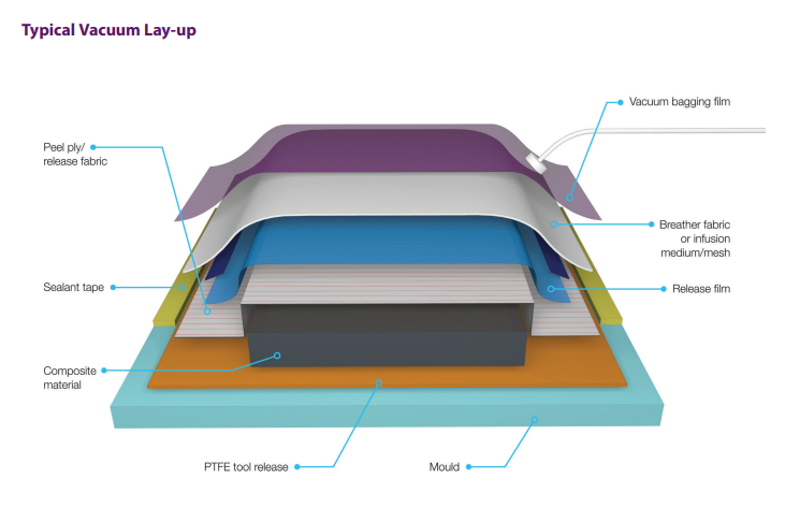

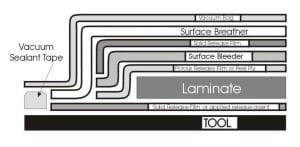

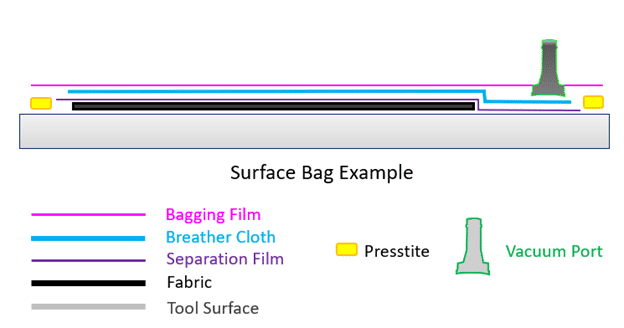

Vacuum bagging: The basics

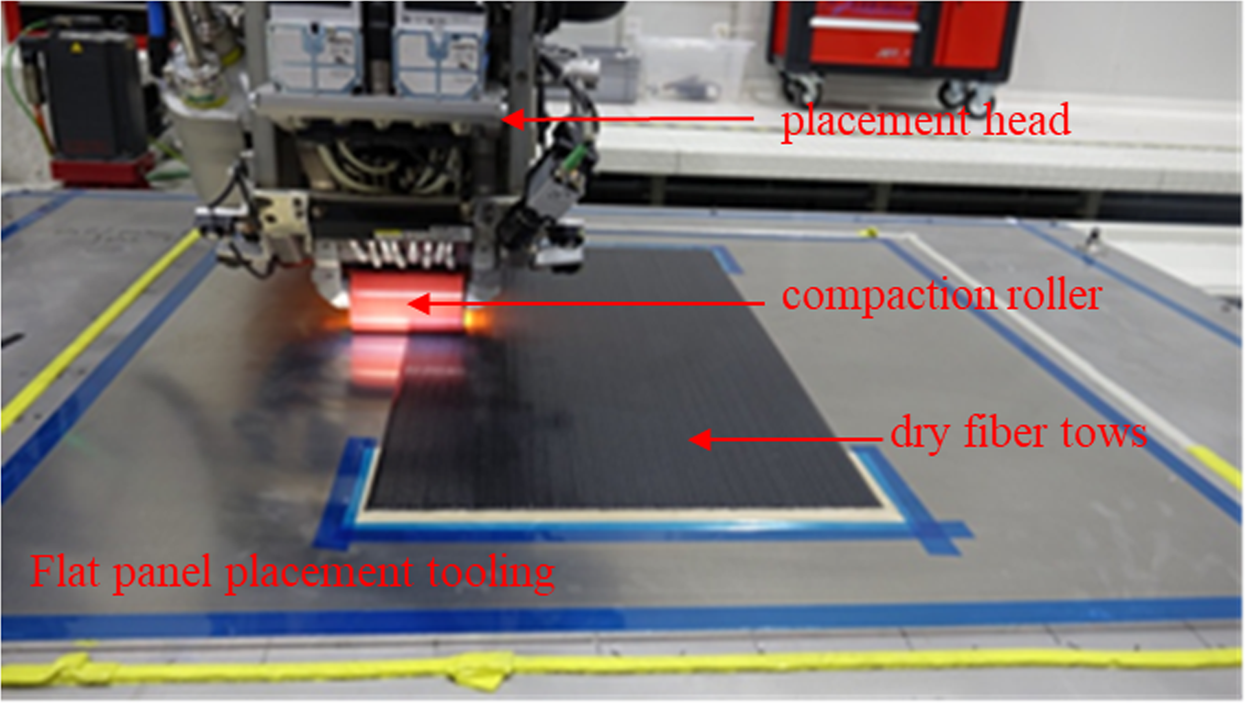

Study on the resin infusion process based on automated fiber placement fabricated dry fiber preform

FUNCTION: Reduce the resin content of the product, make the surface of hand layup products smoother and more beautiful. And there is no excess resin

Peel ply (40x400) for Glass Fiber Vacuum Infusion Process Bagging Tools for Hand Lay-up High Temperature Resistant

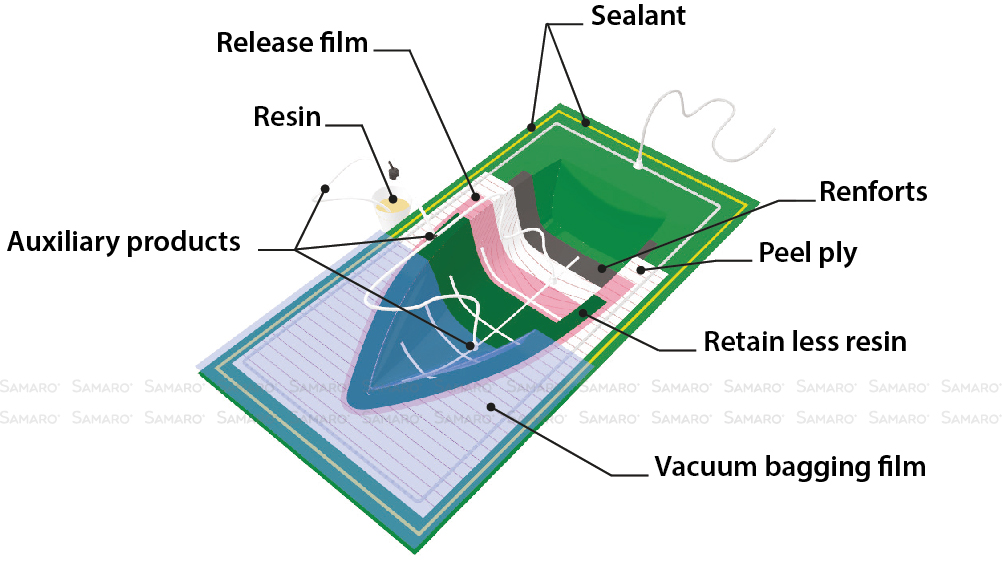

The infusion process step by step. - Samaro

Breather Cloths – Why The OZ Rating Matters - Composite Envisions

Process Materials from Aerovac Offer High Vacuum Integrity Needed in Marine Manufacturing - Composites One - Composites One

Vacuum bagging materials for composites

Vacuum Assisted Resin Infusion Molding

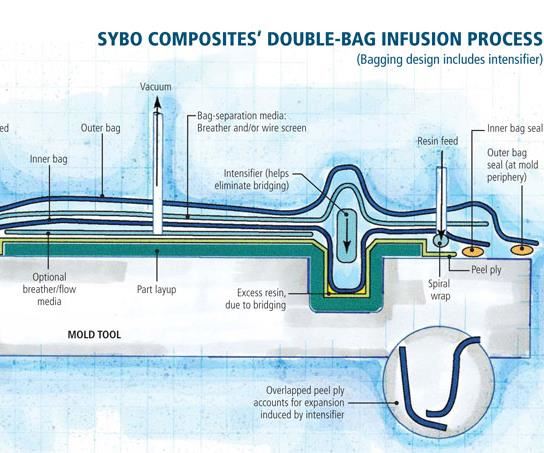

Double-bag infusion: 70% fiber volume?

Understanding vacuum bagging layers in production, repair

Airtech Ipplon® KM1300 – Nylon Vacuum Bagging Film - Composite Envisions

Composites One Offers Manufacturing Efficiencies with Aerovac Kitting Solutions

A new cost-saving vacuum infusion process for fiber-reinforced composites: Pulsed infusion - Maria R Ricciardi, Vincenza Antonucci, Massimo Durante, Michele Giordano, Luigi Nele, Giuseppe Starace, Antonio Langella, 2014